Boxcar Safety is a Major Priority at Arnold Company

There are two main types of boxcars that we provide safe and efficient solutions for: Plug Doors and Sliding Doors. As you may know, the plug door has a handle which is turned to open the door outward before sliding the door over and completely open. With respect to both plug doors and sliding doors, you may or may not know that there are many safety risks and productivity issues that can come into play when opening these types of boxcars (freight railcars).

Use the tabs below to learn more about the safety risks and productivity concerns as well as our solution

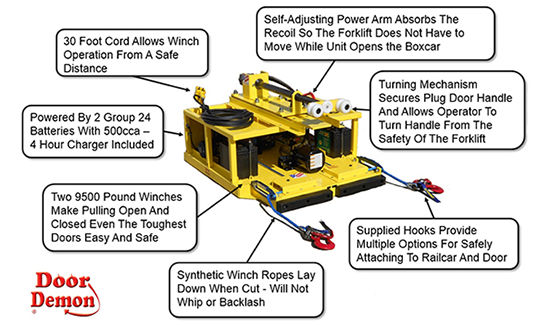

As you can see in the photo above, the employee is either opening or closing the plug door which involves turning the plug door handle. The safety concern here is that these handles often store energy which causes the handle to spin uncontrollably when there is tension on the handle. This energy can be stored as a result of shifted load during transport or when a door was not closed properly.

The results of uncontrolled spin due to stored energy in the handle have resulted in reports of broken fingers and hands and even a dislocated shoulder.

We had a customer call us recently that received a boxcar with the words “ARMBREAKER” written on it. While that serves as a good heads-up, problematic plug doors are not always that obvious.

Another source of injuries due to stored energy involves the tension when using a manual winch, chain, or “come-along” to open a boxcar sliding door. Take a moment to study the photo above. Given the location of the worker’s head, what would happen if this chain breaks or slips?

This is a potentially tragic accident waiting to happen. Even though the employee is wearing a hard-hat, the whiplash effect of a broken chain could have a devastating outcome.

A third source of injuries can be the worst. This can occur when the load has shifted during transport and an employee is standing in front of the boxcar door (or in the danger zone) when the door is opened.

Another variation of this issue is when the door is damaged. The door can fall off its track on the boxcar and can crush nearby employees and/or equipment. While the proper boxcar safety checks can help prevent this, ideally an opener solution that removes the employee from the danger zone is ideal.

Over time, employees have come up with several methods to deal with opening boxcar plug doors and sliding doors…many of which are quite concerning.

At first, tapping the plug door handle with a hammer seems to be “okay”, but when you see the note to “be prepared to drop the hammer and move away”, it gets a bit scary.

An extension pipe for a plug door handle can work if you choose the correct length for what is needed. If you choose poorly, you are likely to simply create a longer weapon.

Employees have been known to ram the boxcar doors with a forklift to get the open. Also, a chain is often connected to a forklift or truck to pull the sliding doors open. While these efforts may seem necessary at the time, it is not safe and can do quite a bit of damage to the boxcar.

When the boxcar is new, things should work well, right? The real question is, “Will the car have issues?” The answer: “Yes they will.” We’ve been told that on average a new or completely refurbished boxcar door often comes back for repair after only minimal usage.

Click HERE for to view our complete solution offering for opening boxcar plug doors and sliding doors