Still using a sledgehammer to unload railcars? It’s time to upgrade to something safer and smarter.

Railcar unloading is one of the toughest jobs in the grain and material handling world. When materials get stuck, backed up, or frozen inside hoppers, it can shut down your operation and put your workers at risk. That is why industrial vibration equipment is now considered the only safe and effective way to handle these stubborn loads.

We offer three core models of roller railcar vibrators that help keep product moving and crews safe: the CR55, CR65, and CR78. Although these air-powered vibrators look similar, they are engineered with very different force and frequency combinations. Choosing the right one depends on your material, environment, and how aggressive you need the vibration to be.

Let’s break down the differences and show you how to use each one most effectively.

Why Use Railcar Vibrators in the First Place?

Here’s what the right vibration system helps you accomplish:

- Improves worker safety by eliminating the need for hammers or manual force

- Speeds up unloading so railcars spend less time tied up on-site

- Protects your equipment from stress and potential damage

- Keeps materials flowing, even when moisture, temperature, or density are working against you

If you’re dealing with material that clumps, cakes, freezes, or sticks to the side of hoppers, a vibration solution is not just helpful—it is essential.

Meet the Roller Railcar Vibrators Lineup

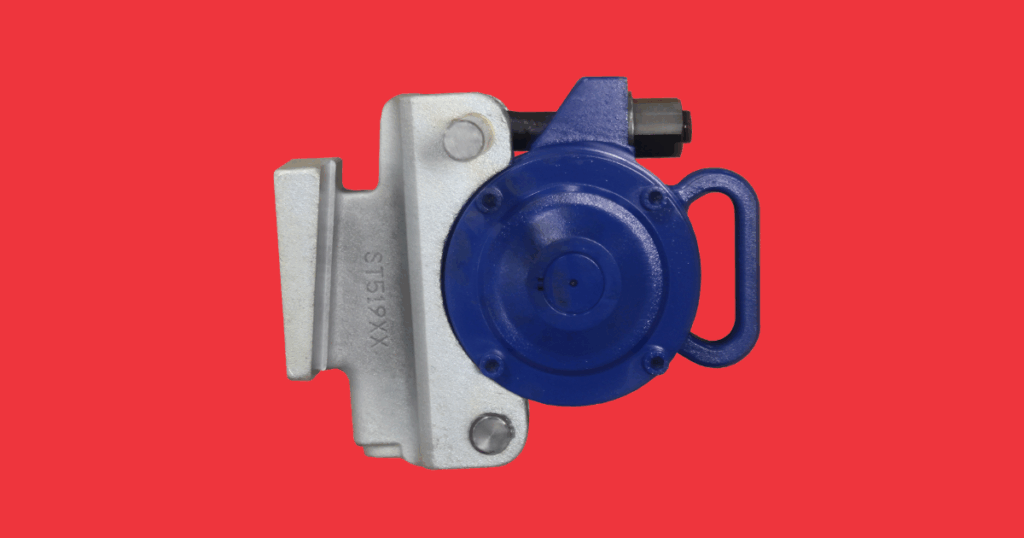

Each model in this series uses compressed air to power a steel roller inside a chamber. This rotating roller generates intense vibration, which transfers directly to the railcar hopper to break up compacted materials.

Key Differences at a Glance

| Model | PSI | CFM | Frequency (VPM) | Force Output (ft-lbs) | Best For |

| CR55 | 90 | 58 | 9,000 | 5,700 | Lightweight powdery materiels |

| CR65 | 90 | 55 | 7,000 | 6,500 | General-purpose railcar unloading |

| CR78 | 90 | 50 | 5,500 | 8,100 | Heavy materiels, High-moisture or sticky loads like DDGS |

| CR78/55 | 90 | 108 | combined | Combined 14600 | Frozen, hardened, or very dense materials and High-moisture or sticky loads like DDGS |

Let’s look at each model more closely.

CR55: High Frequency. Moderate Force. Maximum Agitation.

The CR55 is the fastest model in the series, delivering 9,000 vibrations per minute at 90 PSI. While it doesn’t have the highest impact force, its rapid-fire frequency helps loosen loads that are sticky, wet, or prone to bridging.

Ideal Applications:

- Distillers grain (DDGS)

- Wet meals

- Hot, humid material loads

- Bridged or arched flow

- Light powdery products that don’t flow

The CR55 shines when speed and finesse matter more than brute force. It vibrates quickly to rattle loose clumps without damaging the hopper or over-shaking delicate materials.

CR65: The Balanced Performer

Sitting between the CR55 and CR78 is the CR65, offering a blend of moderate force and frequency. It is perfect for operations that need versatility in a single unit.

Ideal Applications:

- General use across multiple products

- Facilities that handle a range of materials

- Railcar yards with changing weather conditions

If your site unloads many types of product and you want to keep your fleet standardized, the CR65 is your most flexible solution.

CR78: Heavy Force for Heavy-Duty Loads

The CR78 is all about strength. It generates a powerful 8,100 ft-lbs of force, perfect for breaking up compacted or frozen material that simply will not move.

Ideal Applications:

- Frozen grain or meal

- Extremely dense or settled product

- Winter railcar unloading

- Distillers grain (DDGS)

- Wet meals

- Hot, humid material loads

- Dual-sided hopper vibration setups

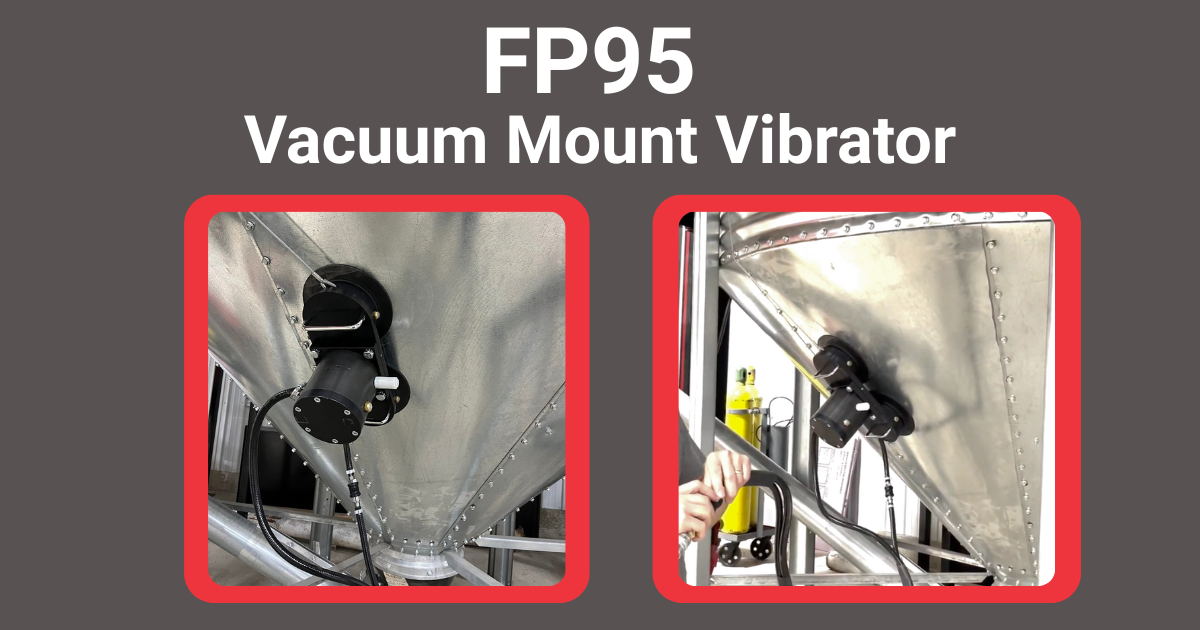

In these tough conditions, operators often run a CR78 on both sides of the railcar. This technique applies equal force to both hopper walls, helping the frozen material slide free with minimal resistance.

Real-World Solutions: Mixing Models for Maximum Efficiency

In some situations, using just one vibrator model is not enough. For materials like distillers grain, which is often loaded hot and becomes sticky as it cools, a combination of vibration types can dramatically reduce unload times.

The Proven Combo Strategy:

Left Hopper Side: CR78 for high force

Right Hopper Side: CR55 for high frequency

This method attacks the material from two angles—breaking it loose with force while shaking it free with speed. The result? A process that once took hours now possibly takes only 20 to 30 minutes.

How to Choose the Right Vibrator

Not sure which model you need? Start by asking these five questions:

- What material are you unloading?

Sticky grains need speed, frozen grains need force. - What environmental factors are present?

Winter conditions often require the CR78. - Is the product loaded hot or cold?

Hot, humid materials benefit from a combo approach. - How much air volume is available?

Make sure your plant’s air supply matches the CFM requirements. - Are you unloading on both sides of the car?

Dual-sided vibration can dramatically improve results.

If you are still not sure, we are here to help. Contact our vibration experts and we will help you build the safest and most efficient unloading system possible.

Safety and Productivity Go Hand-in-Hand

For safety managers, operations leads, and EHS professionals, preventing injuries is always the top priority. But safety doesn’t have to come at the cost of productivity. The right vibration equipment keeps your workers off the hoppers and your materials moving faster than ever before.

No more sledge hammers. No more guesswork. Just clean, fast, safe unloading.

Ready to Make the Switch

Choosing the right roller railcar vibrator is about more than specs. It is about making your worksite safer, faster, and more productive.

Explore the full line of railcar vibrators or contact us directly to discuss your specific unloading challenges. Our team will help you design a system that works—no matter what is stuck inside your hopper.

Request your vibration solution today and move your operation forward with confidence.