Arnold Company’s Door Demon® line of railcar openers, hopper trailer openers, and vibration equipment improve safety and increase efficiency for the ethanol receiving industry.

Safety and speed are critical factors throughout the process of receiving ethanol. As a manufacturer of unloading equipment for railcars and hopper trailers, Arnold Company specializes in providing custom safety and productivity solutions that meet the complex needs of the ethanol receiving industry.

Arnold Company is undoubtedly best known for its flagship Door Demon railcar hopper gate openers, which come in a variety of types and specifications. On the hopper car side, these include manually operated, hydraulic, DC battery-, electric-, and air-operated openers. Within those categories, variations include portable, beam-, forklift-, conveyor-, and skid-steer mounted units.

“We truly understand the challenges associated with railcar opening. Not only do we have the broadest product line in the industry, but we also have the ability and expertise to customize for our clients’ individual needs,” said Albert Middeke, Arnold Company President.

Ensure full capacity with the Arnold Company’s full line of railcar unloading solutions

In 2017, Arnold Company introduced the Door Demon HTO, the world’s first handheld, air-powered hopper trailer opener. This unit’s design assists operators with opening trailer gates safely and efficiently by incorporating the proper amount of torque and speed. The Hopper Trailer Opener allows the operator to remain in full control, keeping both the operator and the trailer gate safe.

“Opening hopper trailers manually isn’t an easy job,” Middeke stated. “Operators start seeing strains, motion injuries and fatigue set in. The HTO is intended to eliminate those issues, making the job of opening grain trailers safe and more productive.”

View the July 2019 edition of Ethanol Producer Magazine for the latest ethanol industry news

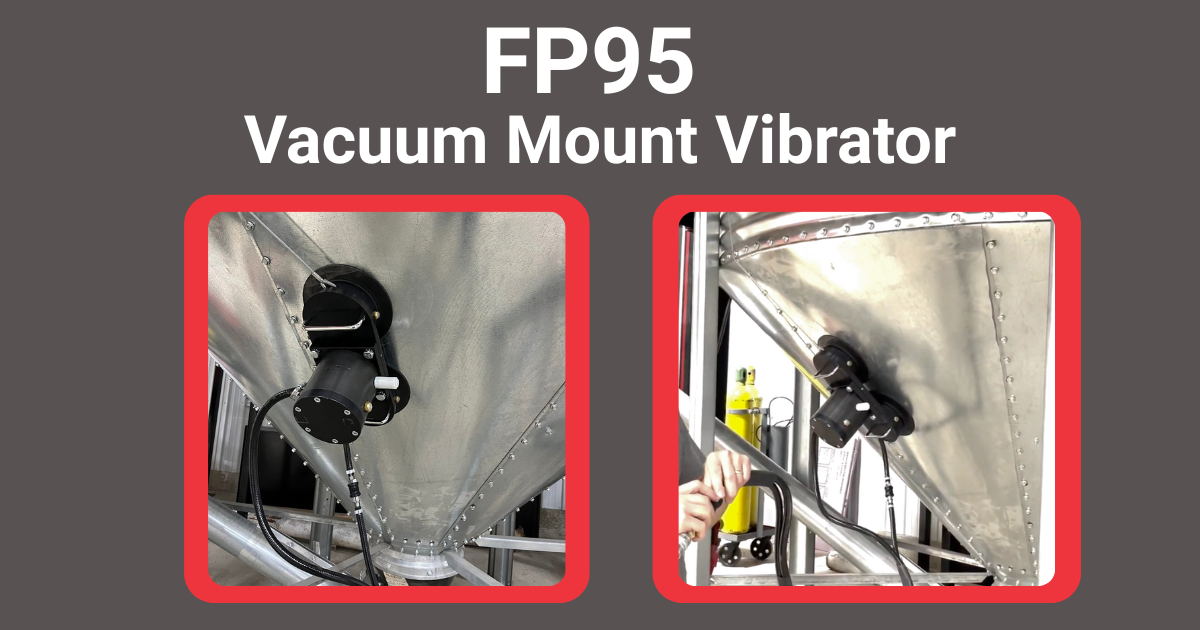

In addition, Arnold Company’s reliable and durable vibration solutions are designed to make working in challenging environments safer, faster, and more efficient.

“Our customers recognize and appreciate that we can help them find a custom product solution, even when their layout isn’t standard,” Middeke added.