Prepare your operators who face repetitive, challenging unloading tasks with durable equipment that gets the job done safely and improves productivity.

Using unreliable unloading equipment can make the job of material receiving much more difficult than necessary. Lack of equipment or equipment that is unsuitable for certain work environments further compromises safety and efficiency.

Oftentimes, operators end up relying on manual shortcuts or miscellaneous tools to try and make up for valuable features their equipment lacks. Without proper tools, operators remain at risk for impact injuries, overuse injuries, and the like.

Let’s explore 4 common scenarios from a variety of work environments that could benefit from having the proper tools on-hand for difficult jobs. For these challenging unloading tasks, durable and safe equipment is critical to success.

Challenge #1: How can we reduce operator fatigue and increase safety while opening railcar hopper gates in a high-volume environment?

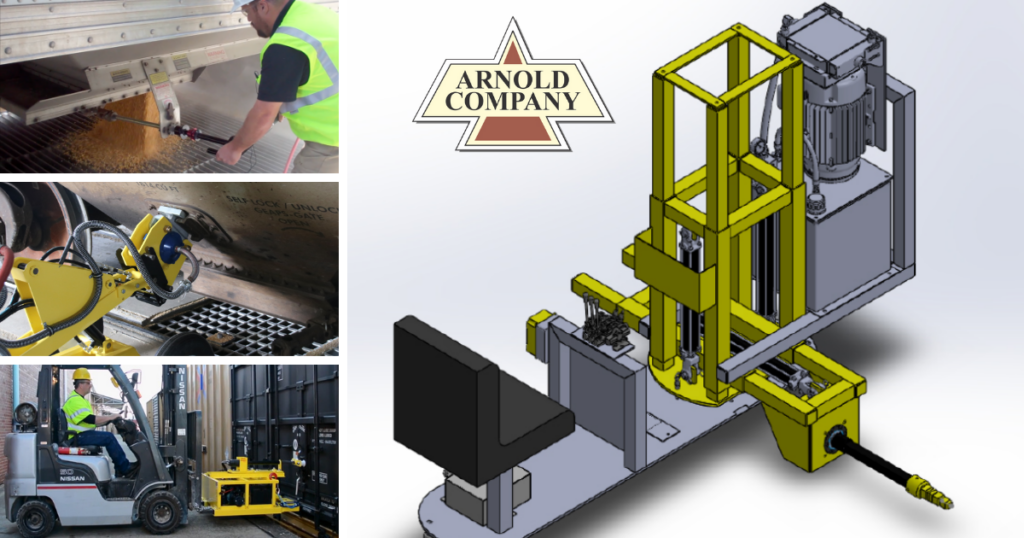

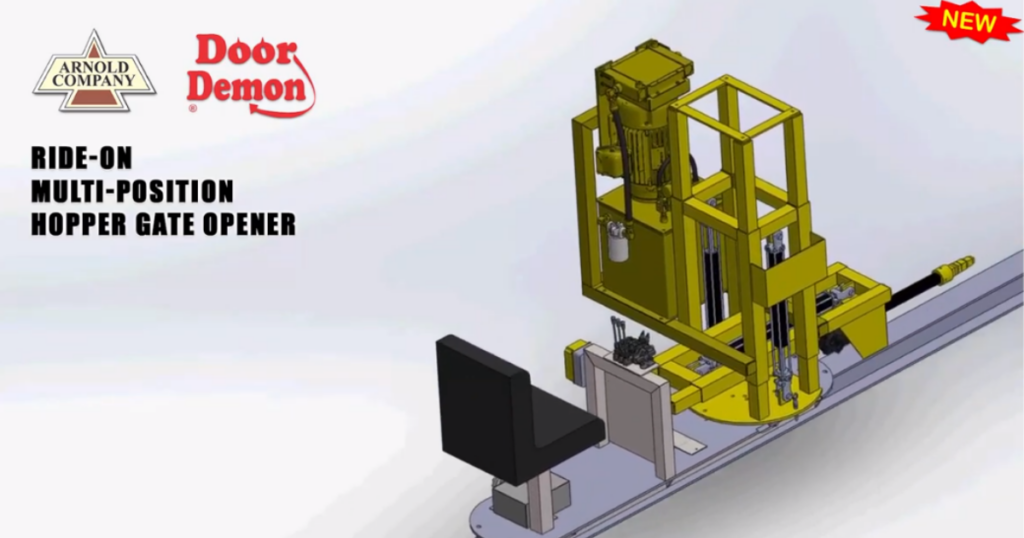

Solution: Introduce a hopper gate opener specifically designed for high-volume applications.

The Ride-On railcar hopper gate opener is the perfect solution in instances where significant volumes require a single operator to unload railcars for an entire shift.

This quiet and comfortable unit offers a higher level of automation, top speeds, and power for users. Operators can remain seated while they work, with easy access to simple controls. The unit comes standard with our highest speed and torque options. In addition, features such as adjustable speed, adjustable seating, railcar remote control shelf, and a built-in hydraulic oil cooler make this unit a real game changer.

Challenge #2: Is there an alternative to physically cranking open hopper trailers by hand?

Solution: Invest in a flexible, handheld unit that is automated and safe on trailer gates.

The patented Hopper Trailer Opener was invented to help eliminate issues such as strain, motion injuries, and fatigue that operators can face when opening too many trailer gates. The world’s first handheld, powered grain trailer opener features include:

- Controllable opening speed and continuous torque

- 3 quick-connect interchangeable trailer sockets

- Air-powered for safe use in dusty environments

- Lightweight, yet rugged for all day use

“It’s the best option out there. It’s very user-friendly and it saves labor by putting less strain on the employees than cranking hopper gates by hand. It also speeds up the unloading process.” Paul Mancini, Farmer’s Grain Terminal

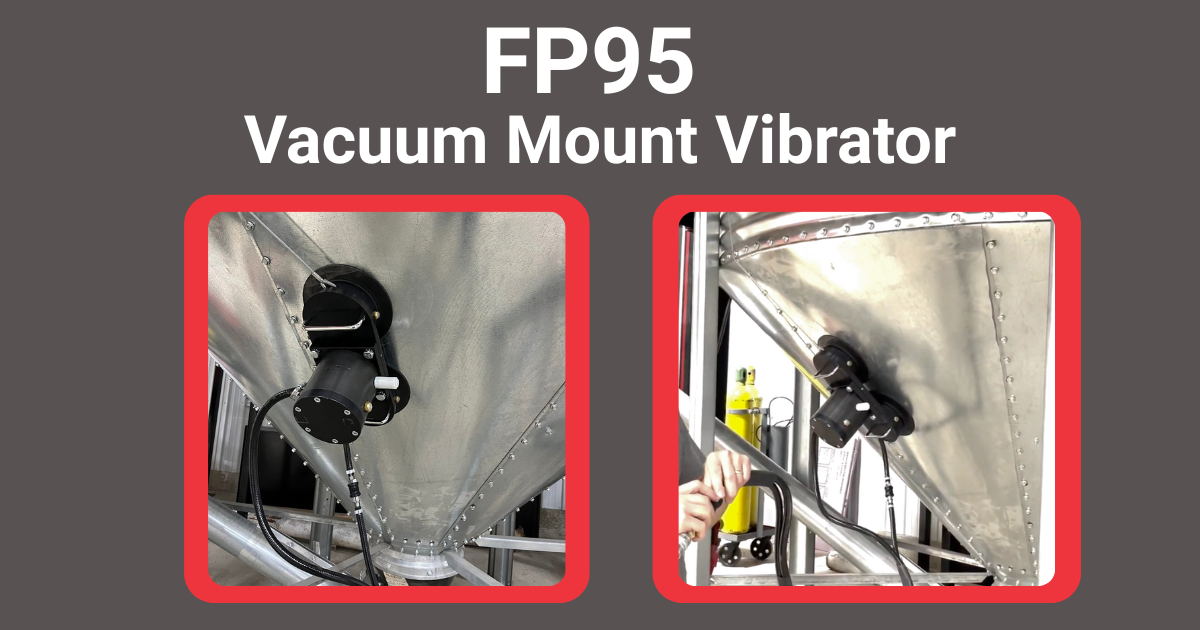

Challenge #3: How can we improve material flow while unloading railcars?

Solution: Incorporate high-quality vibration solutions.

Our line of pneumatic roller railcar vibrators and piston vibrators offers a full range of frequency and force, helping improve material flow during the unloading process. Our roller vibrators have only three internal moving parts, resulting in an extended life and minimal maintenance.

Read our recent case study to learn how we helped a customer shipping prilled ammonium nitrate across the country improve material flow and give their operators major relief from manual hammering.

Challenge #4: Are there solutions that help prevent injuries from poorly loaded or damaged boxcars?

Solution: Select the right boxcar opener unit that meets the unique challenges of your environment.

Boxcar openers minimize the hazards of opening and closing boxcar doors. At Arnold Company, we work to accommodate your operation’s unique needs, such as:

- The space available between the dock and the boxcar

- The location of the receiving dock in respect to your facility

- The type of boxcars received. For example, plug doors, sliding doors, or both

Reduce the risk associated with damaged boxcars by removing the operator from the hazardous area. Utilize a boxcar opener for sliding doors or plug doors (or both) that mounts to a forklift device or acts as a stand-alone unit.

For more information, educate yourself and your team on the do’s and don’ts of boxcar unloading.

American-Made and Built to Last

At Arnold Company, our Door Demon line of railcar openers, hopper trailer openers and vibration equipment are designed to run all day, dramatically improving safety and efficiency for your facility, and more importantly, your employees.

Our equipment is Made in the USA at our Trenton, IL facility. We pride ourselves in building high-quality equipment that is built to last.